Do you want to understand the role of air conditioner capacitors and how they keep your cooling system running smoothly? If yes, then this article is just for you!

In this comprehensive guide, we’ll discuss the different types of AC capacitors, their purpose and maintenance tips so that you can ensure efficient cooling in your space.

The capacitor is an important component of any air conditioning cooling system. It is responsible for helping the compressor motor start and run properly and helps to maintain optimal efficiency while running. By understanding how capacitors work, we can better understand why they may need periodic maintenance or replacement, and how they can help improve the performance of a cooling system.

Capacitors are electrical components made of two metal plates separated by an insulating material known as a dielectric. The capacitor allows the electric current from the motor to build up before going through the rest of the system, which increases starting torque, reduces startup surge current and lets the air conditioner motor to start in a more controlled manner.

It also helps to reduce noise coming from the compressor motor and helps keep it running at its peak efficiency by providing efficient current without any further delay as it passes through other electrical components such as circuit breakers. The capacitor also plays a role in maintaining correct voltage levels by “smoothing out” any fluctuations due to heavy load demands that are placed on it when operating at high speeds.

In short, capacitors help regulate current flow throughout an AC’s system which allows it to perform its job more efficiently while avoiding damage due to power fluctuations or excess energy consumption during startup or operation.

Explanation of what air conditioner capacitors are

Air conditioner capacitors are electrical components that help the air conditioner’s compressor and fans to run. The most common type is called a start-run capacitor, which stores electrical energy and helps the motor to efficiently control the speed of an alternating current (AC) motor.

Capacitors provide AC motors with the jolt of electricity they need at startup, and then continue to provide power during operation. The start-run capacitor works in conjunction with a relays or contactors to assist in the smooth start up of the compressor, fan and other components. Without capacitors, motors will require more power to reach their peak torque output and motors may be unable to maintain efficient performance due to inadequate power supply.

Not all air conditioning systems use capacitors; however, those that do are typically more energy-efficient than those without them. If an air conditioner’s capacitor fails or needs replacement, it can cause serious damage to both compressor and fan motors as well as internal circuits if left unaddressed.

Importance of capacitors in AC systems

Capacitors play a key role in the efficient functioning of an air conditioner, as they are responsible for increasing the system’s start-up and running power. Air conditioners use two types of capacitors. The start capacitor helps the compressor motor get started and is used only momentarily at startup or when briefly restarting after short periods of power interruption.

A run capacitor keeps the compressor motor running smoothly between startups and is typically rated from 5 to 70 microfarads (µF). In air conditioning systems, capacitors are generally connected in parallel with motors to increase their current rating by a factor of up to six times when starting or operating under high load conditions.

Additionally, capacitors help reduce harmonic distortion in the electrical supply, offering protection against motor windings damage and other problems associated with charge separation and current variations inside the motor.

Overview of what the guide will cover

This guide gives a comprehensive overview of what role air conditioner capacitors have in cooling systems and why they are necessary. It explores the different types of capacitors, the advantages each type offers, and it provides an overview of their installation requirements.

Additionally, this guide examines common problems associated with capacitors and provides solutions to restore proper functioning.

Finally, this overview covers safety protocols when troubleshooting air conditioner capacitors to ensure safety and prevent damage to components or personnel.

Capacitor Specifications

The specifications for capacitors are defined by the manufacturer and provide the necessary information for selecting and using capacitors in air conditioning equipment. The most important of these is the voltage rating, which defines the maximum amount of electrical pressure a capacitor can hold without potentially damaging itself or other parts of the system.

Other specifications include capacitance, which measures how much energy is stored in a capacitor; wiring type, which indicates if it’s a single-phase or two-phase system; surge current rating, which indicates how much current it can take at startup; and dissipation factor ratings, indicating how much heat energy is safe to dissipate during usage.

It’s important to note that different manufacturers may have their own set of measurements, so always check before buying or installing a replacement capacitor.

Capacitance

The amount of capacitance, or electrical energy storage capacity, for a specific air conditioner is determined by the distance between the plates and the material placed between them. The greater the distance, or preferably thicker material (also known as dielectric) that is able to withstand higher voltage without deterioration, then greater total capacitance can be achieved. This process is reversed to reduce the capacitance in an air conditioner; the gap between plates and dielectric material remain closer together in review.

An easy example to help understand this complex process might include a water storage container consisting of two metal plates with material holding them apart. The water represents electrical energy that could be used for other purposes such as cooling a room; thus eliminating excess heat produced from everyday activities. In this situation, electric current that flows into one of the metal plates must “wait” until it is ready for use (in this case releasing cool air). That waiting period would be determined by how much water storage capacity the container had when it was full of water; equivalent to a capacitor at full charge within an A/C system. As with other components of an air conditioning system, if capacitor strength is not enough to properly support components, then overall performance suffers and parts may even fail over time.

Voltage Rating

Finding an air conditioning capacitor with the right voltage rating is critical to ensuring your cooling system performs optimally. Generally speaking, most air conditioner or heat pump systems use a dual-run capacitor that has three connection terminals — a common, a fan and a compressor — and two microfarad ratings (MFD) for the fan and compressor connections.

When selecting an AC capacitor, you’ll want to consider two factors: voltage rating and MFD. The typical voltage rating is either 370 or 440 volts, with some models rated up to 600 volts. Before replacing your existing capacitor, make sure you determine its exact voltage rating; if it’s incorrect for your system, it won’t be able to provide enough starting torque for the compressor and could cause damage throughout the entire cooling system. A higher tempature can also decrease cooling efficiency so be sure to select an air conditioner capacitor that can withstand the temepratures in your environment.

Temperature Range

The temperature range of an air conditioner capacitor is an important factor in determining the lifespan and performance of the unit. Capacitors come in two varieties: single-phase and three-phase. Single-phase capacitors are used in cooling systems that have only one fan, while three-phase capacitors are necessary for multiple fan systems.

In general, single-phase capacitors have a higher temperature tolerance than their three-phase counterparts. The operating temperature range for a single-phase capacitor is between -25°C and 70°C (-13°F to 158°F), while for a three-phase cap it’s between -30°C and 105°C (-22°F to 221°F). If the temperature range for your capacitor exceeds these numbers, you should replace it as soon as possible.

Also, bear in mind that many types of capacitors require ambient temperatures between -40°C(-40°F) and 85°C (185 °F) or 0 to 45 °C (32 °F to 113 °F) to maintain their effectiveness. If your cooling unit operates at temperatures outside this range, you should consider using different kinds of capacitors or alternate methods of powering your fan system. Of course, always consult your owner’s manual or contact a qualified technician when making any changes to your system’s components.

Size and Shape

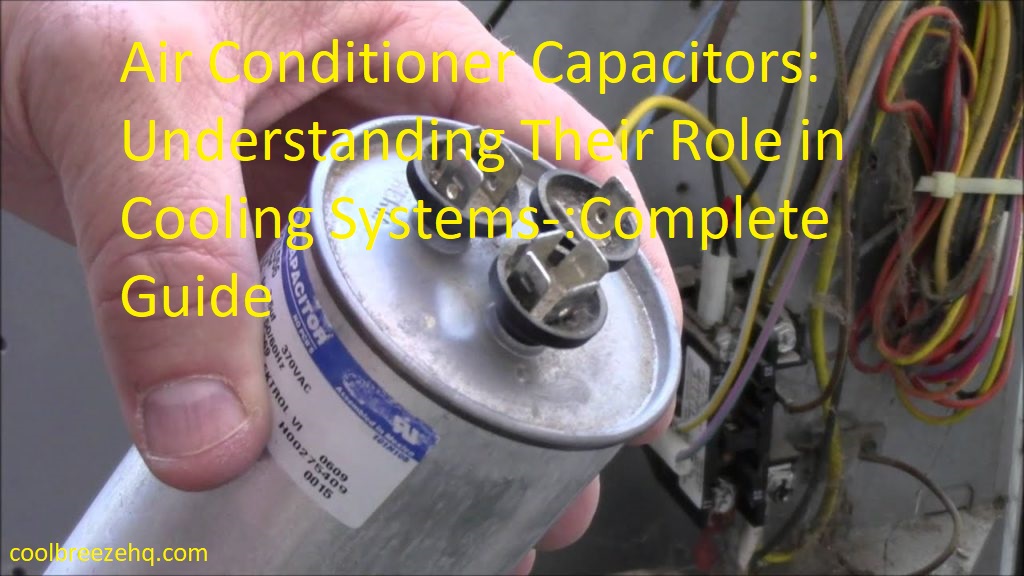

The size and shape of capacitors can vary significantly depending on their intended application. In air conditioning systems, these components are often built with round canisters (usually containing 4 or 5 individual capacitors) and typically measure between 1-3 inches in diameter. These larger canisters may also contain a holder or strap for mounting the unit onto the system’s panel, while some models may feature small eyelets that allow them to be connected directly to other electrical components.

It is important to note that capacitors used in ac systems are also capable of having various overall heights based on the optional screw terminals added for easy attachment. Terminals can be found in a variety of sizes, but it is important to choose one that will provide enough space for any necessary wiring without compromising the unit’s physical stability.

Capacitor Problems and Troubleshooting

A healthy capacitor is crucial for an air conditioner or cooling system to work properly. Unfortunately, the components can degrade and malfunction over time due to factors such as age and exposure to extreme temperature fluctuations. Faulty capacitors can cause a wide array of issues, many of which are easy to troubleshoot.

To diagnose capacitor problems, it’s important to first understand the basics behind them and their role in the system. In a nutshell, an air conditioner’s capacitor is responsible for providing an electrical charge that helps start up motors and keeps them running. This component is usually located outside the unit near the condenser area and looks like a silver cylinder with two terminals on top that are labeled “run” or “start”. It also contains several layers of metal oxide cylinders that store electrostatic charge.

When diagnosing potential capacitor issues, it’s important to observe common symptoms such as flickering lights, buzzing noises coming from the machine, loss of power/cooling performance, and hot spots on/near the component itself. Additionally, poor insulation or shriveled capacitors are classic signs of failure which require either replacement or repair by a professional HVAC technician.

If airflow appears weak or restricted in any way then that could also be a symptom of capacitor problems since this component regulates the amount of current sent to different subsystems inside any cooling system. The first step in such cases should be inspecting all parts including filter mesh panels and coils for signs dirt build-up while studying voltage readings displayed on various user interfaces if present within one’s living space; note that digital versions may require third-party tools for measuring specific parameters like amperage draw rate., etc.. Ultimately addressing any defective capacitors promptly will help prevent bigger maintenance issues down line!

Common capacitor problems

The capacitor is an important part of any air conditioner’s cooling system, and if it isn’t properly taken care of, it could lead to serious problems. There are several common issues that can arise with capacitors, so it’s important to be aware of those so you can take steps to avoid them.

The most common problem with air conditioner capacitors is contamination. This occurs when dust or debris accumulates on the capacitor’s contacts, or terminals. If too much debris builds up, the current will be blocked and the capacitor will not be able to do its job properly. The best way to keep your capacitor clean is to use a soft cloth and lightly wipe down the unit at least once a month.

Another common issue with capacitors is when they become electrically “open-circuited” due to internal damage from surges in energy or voltage levels. Open-circuiting will prevent your air conditioner from operating correctly and could require professional repair or replacement for effective resolution. Additionally, a broken capacitor can create an electrical hazard and may require immediate attention from an HVAC technician as well as safety measures such as shutting off power to the unit until it can be serviced by a professional.

Finally, bad connections between the terminals of the device can cause weak or impaired performance in the air conditioner’s cooling system due to an inadequate electrical connection that affects charging and discharging capabilities. Inspecting these connections regularly for corrosion or other signs of wear will help you identify problems before they become more serious issues down the road. It is also very important to have your unit inspected by an HVAC professional on a regular basis in order to make sure everything is working properly & safely concerning all aspects within its cooling system including its associated capacitor!

Capacitor testing

Testing a capacitor is one of the most important steps in ensuring the longevity and efficiency of any air conditioning system. While the most accurate way to test a capacitor is with a professional-grade multimeter, there are two easy ways to test the capacitors. The first method involves testing for resistance and capacitance and determining whether it is within range and/or defective. The second method involves using an amp meter to determine current flow through the capacitor.

Resistance Test: This can be done several ways, but generally requires removing wiring from the unit. Using an ohmmeter or multi-meter, you will check each wire connection point for resistance between them before testing the actual component itself. A good, undamaged capacitor should have absolutely no continuity measurement between any of the terminals (meaning that all readings should be infinitely high). If you get any kind of reading within range, this indicates that your compressor’s internal wiring may be at fault or that it has become damaged over time – both scenarios will require professional attention. Additionally, certain types of capacitors are designed with a self-wall that helps insulate against external damage. In these cases, you will need specialized tools in order to perform any testing on them safely – otherwise they could explode due to overload or incorrect use of higher volts than what is recommended.

Capacitance Test: This test uses a multimeter or hipot tester to measure the amount of charge stored inside a capacitor’s cell at one time (in farads). A healthy capacitor will always have an AC voltage rating higher than its rated DC voltage – meaning when it charges up with electricity from your AC unit’s motor winding coil, it should be able to store more energy than when it discharges back into your air conditioner’s motor winding coil every few seconds during normal operation. If this is not happening as expected based on your unit’s specifications, checking for dielectric breakdown using a flexible insulated probe can help determine whether or not there is something wrong internally with the component cells before replacing them outright – especially if getting readings outside what should be expected from manufacturer specifications means immediate replacement anyway!

Conclusion

In conclusion, air conditioner capacitors are essential components of cooling systems. They help to ensure that electric motors, such as those found in air conditioners and refrigerators, work properly and efficiently by providing the necessary electrical potential. They enable motors to start rapidly and run smoothly. Without them, motors would overheat and cause damage. Properly functioning capacitors also help to prolong the life of a motor by preventing it from expending too much energy on startup.

When dealing with a malfunctioning capacitor or any other related issue, it is important to contact a professional HVAC technician who can safely diagnose the issue and provide a solution. A properly functioning capacitor is an essential component of any cooling system and should not be overlooked when assessing issues with such systems. By understanding their role in the operation of air conditioners, homeowners can better identify and troubleshoot problems within their HVAC system for improved performance and longer unit life expectancy, saving time, money and energy all around!

FAQ

Does AC capacitor affect cooling?

Yes, AC capacitor affects cooling as it is responsible for providing the necessary power to the compressor and fan motors that are essential components in the cooling process.

What are the different types of capacitors for air conditioner?

The different types of capacitors used in air conditioners are start capacitors, run capacitors, and dual run capacitors.

What are the types capacitors used in refrigeration and air conditioning?

The types of capacitors used in refrigeration and air conditioning are start capacitors, run capacitors, and dual run capacitors.

Can AC run without capacitor?

No, the AC cannot run without a capacitor as it is necessary for providing the initial voltage to start the compressor and fan motors.

What happens when an AC capacitor is not working?

When an AC capacitor is not working, the compressor and fan motors will not receive the necessary power to start, and the AC will not be able to cool the air.

Does the AC capacitor control the fan?

Yes, the AC capacitor is responsible for providing power to the fan motor, which controls the speed of the fan and the circulation of air.

What happens when AC is connected to capacitor?

When the AC is connected to a capacitor, the capacitor provides the necessary voltage to start the compressor and fan motors, which allows the AC to cool the air.

Does AC capacitor make air cold?

No, the AC capacitor does not make the air cold directly. It provides the necessary power to start the compressor and fan motors, which circulates refrigerant through the AC system, and removes heat from the air.

What causes an AC capacitor to overheat?

An AC capacitor can overheat due to several reasons such as age, overuse, overvoltage, or improper installation.

What is the function of a capacitor?

The function of a capacitor is to store electrical energy and release it when needed, which is essential in starting and running motors, like those in air conditioners and refrigeration systems.

See more-

- Best 15000 btu air conditioner 2023

- Best 14000 btu portable air conditioner 2023

- Best tent air conditioner 2023

- Best 10000 btu air conditioner 2023

- Best window air conditioner with heat 2023